Thank you for this information rr64

DC: You are welcome. (rr64 =Dan Case)

I have cleaned the mechanism and lubricated there was quite an amount of debris present . The cancellation device works fine when turning right but the stalk needs to be held in position when turning left or it just returns to neutral . Any suggestions ?

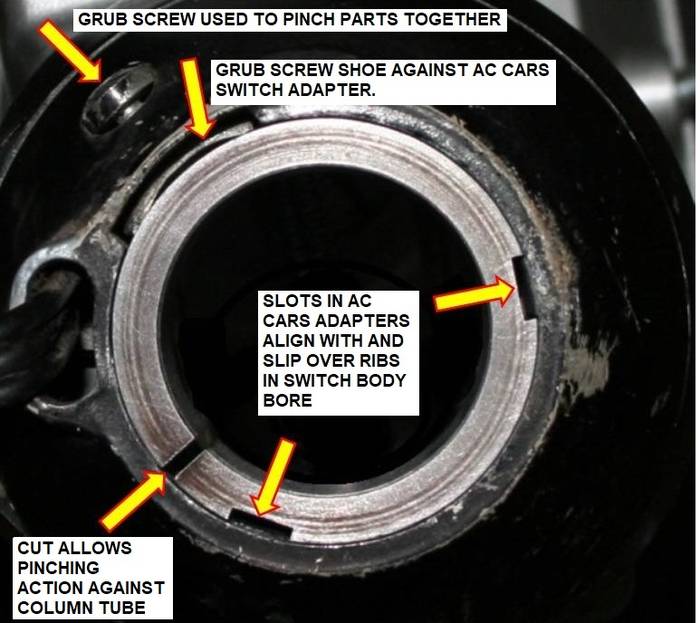

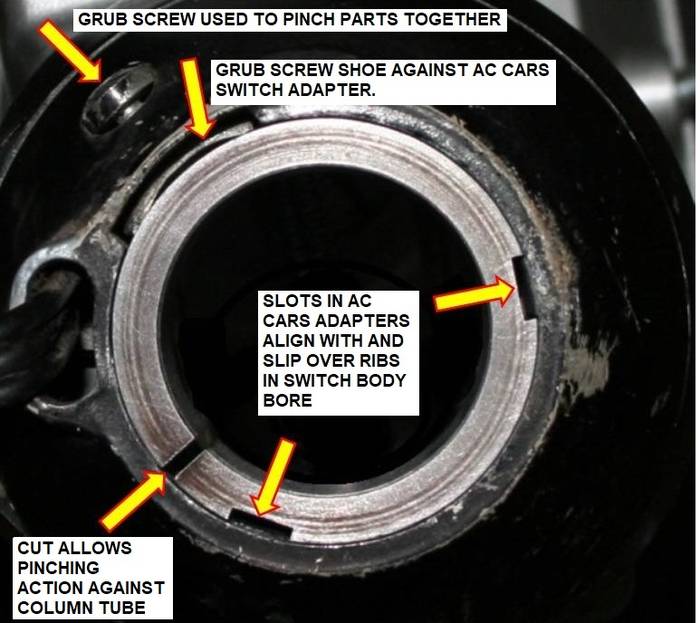

DC: As indicated in the picture in my post, the grub screw contacts the O.E. cancelling lever one direction only. To trip it the other direction one has to turn past it and come back. Many long time owners do just that sometime after their turns are completed one way or the other depending on which side there grub screw sits near the cancelling lever. Having the alignment of the grub screw very near the cancelling lever helps make little movement to trip it. (A similar problem can happen with some of the aftermarket replacement switches also.)

You are quite right the indicator stalk is broken but I have seen today in a previous post on this forum that Gerry of hawk cars had some back in july . If I have no luck I would appreciate the details of someone who might help .

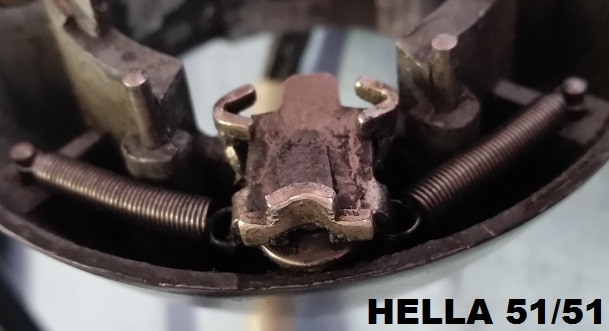

DC: Original Hella® 51/51 assemblies are very rare not on a late Cobra or early 427 Cobra. If he has some, by all means get at least one. Otherwise the choices are used or very rare new old stock VW® production assemblies with enough wire leads to do signals and horn or aftermarket replacements for VW service. SWF® is the most common brand of VW service switch you will find. Be aware that to use any VW or aftermarket switch in an original Cobra application you may have to modify the AC Cars adapter collar, the new switch, or both to make them fit together without using a hammer to beat them together. Parts that people beat into place can be very hard to get back apart. As assembled by AC Cars everything was/is an easy slip fit.

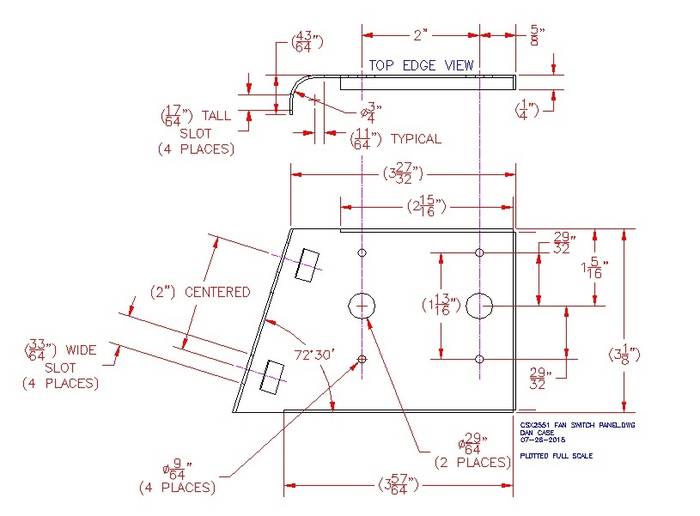

Want more information on this subject, send me private message with your email address. There are three pages with full descriptions and illustration sketches in my electrical file for CSX2201 and later (American market) chassis in my electrical file I have available for owners and restorers. I would send you the entire file.

I would think that any community, town, or city of more than maybe 40,000 or in population would have skilled welders available. Most job shop type machine shops probably have welders in house or somebody they get on contract. They must know that they are being asked to work on a zinc die casting. They can buy filler rod for the job. To get the best results it is best to make a fixture to hold both pieces firmly and in exact alignment. For repairs of rare parts by welding I remove the finish on the parts, make a holding fixture that also allows the welder good access from multiple angles, and prepare the broken ends for fillet welds. The welder’s only function is to do the welding. Even damage to Holley® carburetor zinc die castings can be welded up and once refinished well the repair becomes invisible except via X-ray inspection. Mostly just takes lots of time.

On another related subject my original fuel tank needs replacing it will make a fine pattern , do you happen to know of a reliable supplier of such things ?

DC:

I) If originality is important to you:

A) Is the original tank repairable? The tanks in our cars leaked with fatigue fractured lead solder joints. I desoldered the offending areas and resoldered them but that is at best a temporary fix as lead sealed joints that flex any at all will fracture. After solder repairs I used the tank sealing compound Eastwood® sells. I follow their directions exactly except for every rinse stage I do two more rinses. I did the tank in our black car in the fall of 1997 and had zero issues since using all kinds of street and race fuels street or track.

B) I did drawings many years ago for a friend in want of an original specification tank. He was wanting to replace an aftermarket tank. Two brass bungs must be machined and correct rivets have to be sourced but otherwise any good sheet metal shop that can work to drawings and holotype sample pictures can fabricate a very authentic looking assembly. I would still recommend sealing it as after all lead solder joints will fracture sooner or later.

C) About once a year really nice original tanks come up for sale. Racers don’t want original tanks. One must be aware that CSX2201 and later chassis have mounts for a Stewart-Warner® fuel level sensor and not a Smiths® unit all other chassis used. Again, even if it looked perfect I would seal the inside.

II) If originality is not all that important to you:

A) There is a company in the USA that will seal an old tank inside and out with a proprietary process and materials. THE TANK WILL NOT LOOK ORIGINAL NOR WILL IT EVER AGAIN.

B) More than one parts company has available modern made fully welded tanks in either aluminum or stainless steel.